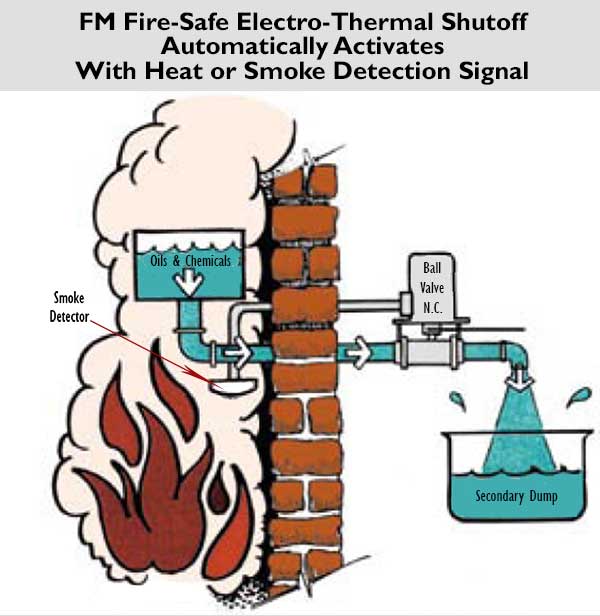

- The FM Fire-Safe Electro-Thermal Link ball valve is activated by either heat or signal from smoke detector to dump flammable fluids to another source.

The fire safe thermal shutoff closes to prevent fueling of a fire in petroleum and chemical processing plants.

In his presentation on Emergency Block Valves (EBV) to the AIChE sponsored Global Congress on Process Safety, Joe Viviano, a process engineer at Technip, cited PG&E’s true cost of not using EBVs on a pipeline: the damages and claims for the 2010 San Bruno, CA, gas main break exceeds over $1 billion. Regulators agree that EBVs would have mitigated the damage by reducing the hour and 47 minutes it took to manually shut off the gas. Viviano challenges flammable media system operators by asking: “When are you really going to get it shut down if it’s manual? And when can you get it isolated? … Considering a lot of fire systems only have a 30-minute rating, there’s a lot of other subsequent damage that occurs from not being able to shut off your source soon enough.” (Sources: AIChE Paper Number 150c: “Emergency Block Valves – A Guide to Selection,” Joseph A. Viviano, P.E., 2012; Mercury News, San Jose CA)

Evaluating EBVs on a cost basis using Dow’s Fire and Explosion Index methodology, an operation can save $350,000 on an installed plant valued at $5,000,000 – as well as save $300,000 per day of down time resulting from a leakage and potential fire incident. These savings are based on estimated damage value of 70% of installed value and a 10% savings from EBV/SIS systems, typical in the industry.

Simple, proven, and Factory Mutual (FM) approved valve assemblies incorporate Emergency Block Valve (EBV) shutoffs with thermal, and even better — electro thermal shutoffs, such as the FM Fire-Safe Thermal and Electro-Thermal shutoffs, available from Assured Automation®.

According to Henry Febo of Factory Mutual, thermal shut-offs are widely used and provide a generally accepted, inexpensive layer of safety. An automatic trigger to shut the flow of flammable media in the event of fire, answers the question, who turns off the fire-safe valve during a fire — the fusible link assembly automatically stops the flow of flammables.

Although the usage of thermal shutoffs is relatively widespread in the industry, process designers are only beginning to learn about, and adopt electro-thermal shutoffs. This allows the EBV to be automatically shut off in response to a signal as well as in response to heat and manual manipulation. The electro component can be triggered by a number of sensors, including smoke detectors or pressure drops, adding another layer of automatic protection.

The multiple layers of protection offered by an FM FireSafe Electro-thermal shutoff assembly include:

- Thermal shutoff in the event of fire

- U.L. listed Electro shutoff in the event of a signal from a smoke detector, gas sensor, or pressure drop sensors

- Local manual shutoff in the event of tank leakage

- Remote manual shutoff in the event of leakage of toxic vapors

To make it simple for process engineers to design, quote and order electro-thermal and EBV assemblies such as the FM approved Fire-Safe Shutoff, Assured Automation’s has released an online configurator to select assembly components. The configurator gives assembly options for:

- Valve Body: Ball Valve, Flanged Ball Valve, Butterfly Valve

- Valve Construction: Stainless Steel, Carbon Steel

- Valve Size: 1/2” up to 12”

- End Connection: NPT, Socket Weld, Butt Weld

- Thermal Link trigger temperature:

- Electro Thermal Link trigger temperature:

- Actuation Position: Normally Open (fail to close) or Normally Closed (fail to open)

- Limit Switch: NEMA 4/4X, Weatherproof or NEMA 4/4X /7 Weatherproof and Explosion proof

FM Fire-Safe Thermal and Electro-Thermal Shutoff Emergency Block Valve Assemblies

The Assured Automation® FM Fire-Safe Thermal and Electro-Thermal ball valve and butterfly valve assemblies are designed to shut off automatically and control hazardous conditions. The ball valve and butterfly valve assemblies are Factory Mutual (FM) approved. The heat actuated, FM & U.L. listed thermal links automatically shut off or open the valve at predetermined temperatures. A unique, removable handle allows the valve to be manually operated at any time without affecting the fusible links. The assembly features include:

- Fire-Safe valves to API 607

- Stainless Steel or Carbon Steel Ball Valve, Flanged Ball Valve, or Butterfly Valves. The ball valves are true “industrial style” full port ball valve, not check valves

- Valve can be operated even while spring pack is armed

- Heavy duty arming device

- Factory assembled and tested

- Thermal Link temperatures from 165°F to 500°F

- Automatic firing device and remote monitoring systems available

- Higher pressure ratings

- Can be manually operated

- Easy to re-set in the field

- Simple field maintenance and repair. No need to remove ball valves from the pipeline for repair/maintenance

The evidence is overwhelming regarding the value of safety systems in the production of chemicals, pharmaceuticals, oil, natural gas and diesel production, alternative fuels, paint and coatings, alcohol, adhesives and sealants, on tank farms and any manufacturing process that involves flammable liquids or gasses. And OSHA’s regulation on flammable liquids (29 CFR 1910.106(b)(4)(iv)(c)), API 553 standard, and NFPA 58 standard all recommend the use of emergency block valves for safety when designing systems for flammable media.

In his seminal paper on Remote Isolation and Shut Off, John F. Murphy recommends installation of Emergency Block Valves for flammables at:

- Loading/unloading lines

- Inlet and outlet of compressors

- Inlet and outlet of reactors

- Inlet of pumps from vessels with 10,000 pounds of flammable material

- At major lines entering or leaving a system of vessels, containing more than 10,000 pounds of flammable chemicals, which operate together to perform a unit operation such as distillation, refrigeration or reaction. For example in an ethylene plant, an EBV is often installed in the feed line to a distillation unit and another EBV is installed in the outlet line from the unit to the next process unit;

- At the battery limits for pipelines containing hazardous materials

John Murphy is a retired process safety engineer that worked for the Dow Chemical Company and as a lead investigator for the US Chemical Safety Board. He presently works as a consultant for the AIChE Center for Process Safety where he has managed several book projects on Layer of Protection Analysis (LOPA) and teaches Process Safety Boot Camp to companies around the world.

Regulations and Standards Regarding Flammables

OSHA 29 CFR 1910.106(b)(4)(iv)(c) – Flammable Liquids

Flammable liquid tanks located inside of buildings, except in one-story buildings designed and protected for flammable liquid storage, shall be provided with an automatic-closing heat-actuated valve on each withdrawal connection below the liquid level, except for connections used for emergency disposal, to prevent continued flow in the event of fire in the vicinity of the tank. This function may be incorporated in the valve required in (b) of this subdivision, and if a separate valve, shall be located adjacent to the valve required in (b) of this subdivision.

ANSI/API 607

Fire Test for Soft-Seated Quarter Turn Valves. The standard covers the requirements for testing and evaluating the performance of straightway, soft-seated quarter-turn valves when the valves are exposed to certain fire conditions defined in this standard. The procedures described in this standard apply to all classes and sizes of such valves that are made of materials listed in ASME B16.34.

API 553, Paragraph 7.2.1

Emergency Block Valves are used to control a hazardous incident. These are valves for emergency isolation and are designed to stop the uncontrolled release of flammable or toxic materials.

NFPA 58 (1979 Edition) 2343

Emergency shutoff valves shall be approved and incorporate all of the following means of closing (see 3168 and 3223):

- Automatic shutoff through thermal (fire) actuation. When fusible elements are used they shall have a melting point not exceeding 250°F.

- Manual shutoff from a remote location.

- Manual shutoff at the installed location.

NOTE: The only proposed change is in section 3168 where the compliance date of December 31, 1978 is moved to December 31, 1980.

Factory Mutual Class Number 7440, May, 1981

Approval Standard for Firesafe Valves

A firesafe valve is one specifically designed for flammable liquid service and which can withstand a direct fire exposure of 15 minutes without excessive internal or external damage.