VA Series

Materials

Body: Nickle Plated Brass

Seals: Viton, EPDM, or Buna

Connections

NPT: 3/8″ to 2″

VIP Series

Materials

Body: Nickle Plated Brass

Seals: Viton, EPDM, or Buna

Connections

G (BSPP): 3/8″ to 2″

VIP-EVO Series

Materials

Body: Aluminum (non-wetted)

End Conn: Ni plated Brass (wetted)

Piston: Chem. Ni plated Brass (wetted)

Seat: PTFE 15% Glass Fiber

Seals: Viton, EPDM, or Buna

Connections

NPT: 3/8″ to 2″

G (BSPP): 3/8″ to 2″

Angle Valves

Materials

Body: SS or Bronze

Seals: PTFE

Connections

NPT: 3/8″ to 2″

Tri-Clamp: 1/2″ to 2″

SV Series

Materials

Body: Stainless Steel

Seals: Viton or EPDM

Connections

NPT: 1/4″ to 2″

RSG Series

Materials

Body: SS or Brass

Seals: FKM

Seats: PTFE

Connections

NPT: 3/8″ to 1 1/4″

SM Series

Materials

Body: Brass or Lead Free Brass

Seals: PTFE

Seats: PTFE

Connections

NPT: 1/2″ to 2″

P2 Series

Materials

Body: PVC

Seals: EPDM or Viton

Seats: PTFE

Connections

NPT: 1/2″ to 4″

Glue Socket: 1/2″ to 4″

101 Series

Materials

Body: Nickel Plated Brass

Seals: PTFE

Seats: PTFE

Connections

NPT: 3/8″ to 3″

26 Series

Materials

Body: Stainless steel

Seals: PTFE & Viton

Seats: RPTFE

Connections

NPT: 1/4″ to 3″

38 Series

Materials

Body: Stainless steel

Seals: PTFE

Seats: RPTFE

Connections

NPT: 1/4″ to 3″

Socket Weld: 1/4″ to 3″

Tri-clamp: 1/2″ to 4″

Ext. Tube Butt Weld: 1/2″ to 4″

36 Series

Materials

Body: Stainless steel

Seals: PTFE

Seats: RPTFE

Connections

NPT: 1/4″ to 3″

Socket Weld: 1/4″ to 3″

Tri-clamp: 1/2″ to 4″

150F/300F Series

Materials

Body: Carbon or stainless steel

Seals: TFM or Graphite

Seats: TFM or 50/50

Connections

150#: 1/2″ to 8″

300#: 1/2″ to 8″

150F/300F Series

Materials

Body: Carbon or stainless steel

Seals: TFM or Graphite

Seats: TFM or 50/50

Connections

150#: 1/2″ to 8″

300#: 1/2″ to 8″

HPF Series

Materials

Body: Carbon or stainless steel

Seals: TFM or Graphite

Seats: TFM or 50/50

Connections

NPT: 1/2″ to 4″

Socket Weld: 1/2″ to 4″

HPF Series

Materials

Body: Carbon or stainless steel

Seals: TFM or Graphite

Seats: TFM or 50/50

Connections

NPT: 1/2″ to 4″

Socket Weld: 1/2″ to 4″

XP3 Series

Materials

Body: Carbon or stainless steel

Seals: TFM or Graphite

Seats: TFM or 50/50

Connections

NPT: 1/2″ to 4″

Socket Weld: 1/2″ to 4″

DSI-WG Series

Materials

Body: Carbon Steel (A216 WCB)

Trim: API Trim 8 (others available)

Connections

150#: 2″ to 30″

300#, 600#, 900#, 1500#: Call

XLB Series

Materials

Body: PFA lined Ductile Iron

Seals: PTFE

Seats: PTFE

Connections

150#: 1/2″ to 6″

V Series

Materials

Body: Carbon or Stainless Steel

Seats: PTFE, TFM, or 50/50

Seats: PTFE, TFM, or 50/50

Connections

NPT: 1/2″ to 4″

150#/300#: 1/2″ to 8″

Tri-Clamp: 1/2″ to 4″

SM Series

Materials

Body: Brass or Lead Free Brass

Seals: PTFE

Seats: PTFE

Connections

NPT: 1/2″ to 2″

30D Series

Materials

Body: Stainless Steel

Seats: PTFE

Seals: PTFE

Connections

Tri-Clamp: 1/2″ to 4″

31D Series

Materials

Body: Stainless Steel

Seats: PTFE

Seals: PTFE/Viton or RPTFE

Connections

NPT: 1/4″ to 3″

33D Series

Materials

Body: Brass

Seats: RPTFE

Seals: RPTFE/Viton

Connections

NPT: 1/4″ to 2″

MPF Series

Materials

Body: Carbon or Stainless Steel

Seats: TFM

Seals: TFM

Connections

150#: 3/4″ to 6″

300#: 1 1/2″ to 6″

PTP Series

Materials

Body: PVC

Seats: PTFE

Seats: EPDM or Viton

Connections

NPT: 1/2″ to 2″

Glue Socket: 1/2″ to 2″

BFY Series

Materials

Body: 316L SS

Seats: EPDM, SIlicon, or Viton

Connections

Tri-Clamp: 1/2″ to 6″

Butt Weld: 1/2″ to 6″

FE Series

Materials

Body: PVC

Seats: EPDM

Connections

Wafer: 1 1/2″ to 12″

FK Series

Materials

Body: GRPP

Seats: Polypropylene

Connections

Wafer: 1 1/2″ to 12″

Lugged: 2 1/2″ to 12″

HP Series

Materials

Body: Carbon or Stainless Steel

Seats: RPTFE

Connections

Wafer: 2″ to 12″

Lugged: 2″ to 12″

HPX Series

Materials

Body: Carbon or Stainless Steel

Seats: Graphite

Connections

Wafer: 3″ to 48″

Lugged: 3″ to 48″

ANSI class 150, 300, 600

HPX Series

Materials

Body: Carbon or Stainless Steel

Seats: Graphite

Connections

Wafer: 3″ to 48″

Lugged: 3″ to 48″

ANSI class 150, 300, 600

ST Series

Materials

Body: Epoxy Coated Ductile Iron

Seats: BUNA or EPDM

Connections

Wafer: 2″ to 12″

Lugged: 2″ to 24″

XLD Series

Materials

Body: PFA Lined Ductile Iron

Seats: Viton

Connections

Wafer: 2″ to 24″

Lugged: 2″ to 24″

061 Series

Materials

Body: PFA Lined Ductile Iron

Plug: PFA Lined Ductile Iron

Connections

150#: 1/2″ to 4″

067 Series

Materials

Body: Stainless Steel

Seals: PTFE

Connections

150#: 1/2″ to 4″

XP3 Series

Materials

Body: Stainless Steel or Carbon Steel

Seals: PTFE, RPTFE, PFA, or Special

Connections

150#: 1/2″ to 12″

300#: 1/2″ to 12″

GVI Series

Materials

Body: Carbon or Stainless Steel

Trim: SS, TFE, or PEEK

Connections

150#: 1/2″ to 4″

300#: 1/2″ to 4″

NPT: 1/2″ to 2″

SW: 1/2″ to 2″

GV Series

Materials

Body: Bronze or Stainless Steel

Trim: Bronze, SS, or PEEK

Connections

NPT: 1/2″ to 2″

Butt Weld: 1/2″ to 2″

GH Series

Materials

Body: Cast Iron

Trim: Bronze or SS

Connections

150# Flange: 2 1/2″ to 8″

300# Flange: 2 1/2″ to 8″

EWG Series

Materials

Body: Carbon Steel (A216 WCB)

Trim: API Trim 8 (others available)

Connections

150#: 2″ to 30″

300#, 600#, 900#, 1500#: Call

DSI-WG Series

Materials

Body: Carbon Steel (A216 WCB)

Trim: API Trim 8 (others available)

Connections

150#: 2″ to 30″

300#, 600#, 900#, 1500#: Call

21 Series

Materials

Body: Stainless Steel

Seats: PTFE

Seals: PTFE

Connections

NPT: 1/4″ to 2″

282 Series

Materials

Body: Brass

Seats: PTFE

Seals: PTFE

Connections

NPT: 1/4″ to 4″

NPT (male x female): 1/4″ to 1″

Solder: 1/2″ to 4″

282LF Series

Materials

Body: Lead Free Brass

Seats: PTFE

Seals: PTFE

Connections

NPT: 1/2″ to 2″

Manual Valves

2-way Ball Valves

NPT: 1/4″ to 3″

Socket Weld: 1/4″ to 3″

Tri-Clamp: 1/2″ to 3″

3-way Ball Valves

NPT: 1/4″ to 2″

Butterfly Valves

Lugged: 2″ to 8″

112LF Series

Materials

Body: Stainless Steel

Seats: PTFE

Seals: PTFE

Connections

NPT: 1/2″ to 2″

282LF Series

Materials

Body: Brass

Seats: PTFE

Seals: PTFE

Connections

NPT: 1/4″ to 4″

NPT (male c female): 1/4″ to 1″

Solder: 1/2″ to 4″

250LF Series

Materials

Body: Lead Free Brass

Seats: PTFE

Seals: PTFE

Connections

NPT: 1/2″ to 2″

Manual Valves

2-way Ball Valves

NPT: 1/4″ to 3″

Socket Weld: 1/4″ to 3″

Tri-Clamp: 1/2″ to 3″

3-way Ball Valves

NPT: 1/4″ to 2″

Butterfly Valves

Lugged: 2″ to 8″

TSV Series

Materials

Valve: Ball or Butterfly

Body: Carbon or Stainless Steel

Seals: Delrin®

Connections

NPT: 1/4″

SW: 1/4″

150#: 1/4″

300#: 1/4″

Lugged: 1/4″

Wafer: 1/4″

FireChek® Series

Materials

Body: Stainless Steel

Seals: Delrin®

Connections

NPT: 1/4″

ISO: 1/4″

FM Fire-Safe Valves

Materials

Body: Carbon or Stainless Steel

Seals: Graphoil

Seats: Xtreme RPTFE

Connections

NPT: 1/2" to 2"

150#/300#: 1/2" to 4"

Lug/Wafer: 3" & 4"

ESD Series

Materials

Body: Carbon or Stainless Steel

Seals: TFM or Graphite

Seats: TFM or 50/50

Connections

150#: 1/2″ to 8″

300#: 1/2″ to 8″

NPT: 1/2″ to 4″

Socket Weld: 1/2″ to 4″

ESOV Series

Materials

Body: Carbon or Stainless Steel

Seat: API Trim 8 or 12

Cover Seal: Graphite

Connections

150#: 2″ to 16″

300#: 2″ to 16″

150F/300F Series

Materials

Body: Carbon or Stainless Steel

Seals: TFM or Graphite

Seats: TFM or 50/50

Connections

150#: 1/2" to 8"

300#: 1/2" to 8"

FM Fire-Safe Valves

Materials

Body: Carbon or Stainless Steel

Seals: Graphoil

Seats: Xtreme RPTFE

Connections

NPT: 1/2" to 2"

150#/300#: 1/2" to 4"

Lug/Wafer: 3" & 4"

HPF Series

Materials

Body: Carbon or Stainless Steel

Seals: TFM or Graphite

Seats: TFM or 50/50

Connections

NPT: 1/2″ to 4″

Socket Weld: 1/2″ to 4″

HP Series

Materials

Body: Carbon or Stainless Steel

Seals: TFM or Graphite

Seats: TFM or 50/50

Connections

Wafer: 2″ to 12″

Lugged: 2″ to 12″

ESD Series

Materials

Body: Carbon or Stainless Steel

Seals: TFM or Graphite

Seats: TFM or 50/50

Connections

150#: 1/2″ to 8″

300#: 1/2″ to 8″

NPT: 1/2″ to 4″

Socket Weld: 1/2″ to 4″

C Series

Materials

Housing: Extruded aluminum alloy

End Caps: Powder coated die-cast aluminum

Torque

Spring Return: up to 56,500 in/lbs.

Double Acting: up to 59,000 in/lbs.

F Series

Materials

Housing: Polyurethane coated aluminum

Torque

Spring Return: up to 13,211 in/lbs.

Double Acting: up to 21,430 in/lbs.

O Series

Materials

Housing: Aluminum with corrosion resistant coating

Torque

Spring Return: up to 25,600 in/lbs.

Double Acting: up to 25,600 in/lbs.

P Series

Materials

Housing: Aluminum with corrosion resistant coating

Torque

Spring Return: up to 25,600 in/lbs.

Double Acting: up to 25,600 in/lbs.

CE Series

Materials

Housing: Ploycarbonate plastic (ABSPC)

Torque

100 in/lbs.

V4 Series

Materials

Housing: Epoxy coated aluminum

Torque

125 or 300 in/lbs.

R4 Series

Materials

Housing: Polycarbonate

Torque

300 or 600 in/lbs.

S4 Series

Materials

Housing: Anti-corrosive polyamide

Torque

up to 2,600 in/lbs.

O Series

Materials

Housing: Diecast aluminum alloy

Torque

up to 8,680 in/lbs.

B7 Series

Materials

Housing: Epoxy powder coated aluminum

Torque

up to 20,000 in/lbs.

FEX Series

Easily Retro-fits on

HPF, 150F, and 300F Ball Valves

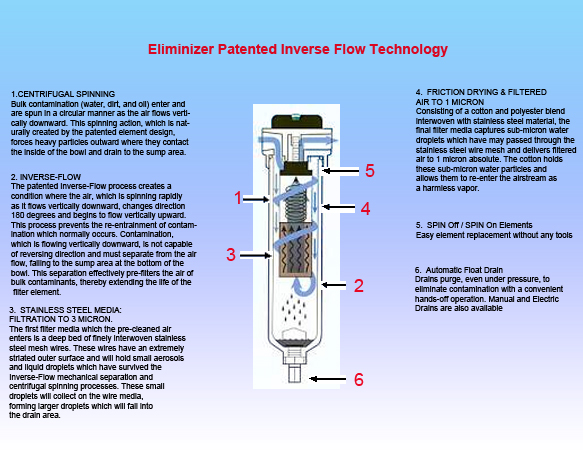

Eliminizer Series

Air Flow

20 to 150 SCFM

Connections

NPT (female): 1/4" to 1"

Filtration

Solids: 1 micron

Water: 100% removal

Eliminizer Combo Series

Air Flow

20 to 150 SCFM

Connections

NPT (female): 1/4" to 1"

Filtration

Solids: .01 micron

Water: 100% removal

01N Series

Materials

Body: Nylon

Connections

NPT: 1″

01A Series

Materials

Body: Aluminum

Connections

NPT: 1″

DM-P Series

Materials

Body: Plastic

Connections

NPT (male): 1/4″ to 1″

MAG Series

Materials

Body: Stainless Steel

Connections

NPT: 1/4″ to 2″

BSPP: 1/4″ to 2″

T-clamp: 1/2″ to 2″

G2 Series

Materials

Body: SS, Aluminum, or Brass

Connections

NPT: 1/2″ to 2″

T-clamp: 3/4″ to 2 1/2″

Flange: 1″ to 2″

TM Series

Materials

Body: PVC schedule 80

Connections

NPT: 1″ to 4″

Glue Socket (female): 1″ to 4″

Flange: 3″ to 4″

WM-PT Series

Materials

Body: PVC sched. 60 or 80

Connections

Glue Socket (male): 1/2″ to 4″

Insertion: 1 1/2″ to 8″

WWM Series

Materials

Body: PVC sched. 60 or 80

Connections

Glue Socket (male): 1/2″ to 4″

Insertion: 1 1/2″ to 8″

LM Series

Materials

Body: Aluminum

Connections

NPT: 1/2″

WM Series

Materials

Body: Epoxy Coated Bronze

Connections

NPT: 1/2″ to 2″

WM-NLC Series

Materials

Body: Lead Free Brass

Connections

NPT: 1/2″ to 2″

WM-NLCH Series

Materials

Body: Lead Free Brass

Connections

NPT: 1/2″ to 2″

D10 Series

Materials

Body: Lead Free Brass

Connections

NPT: 1/2″ to 1″

Flange: 1 1/2″ to 2″

WM-PC Series

Materials

Body: Fiber Reinforced Polymer

Connections

NPT: 1/2″ to 1 1/2″

WM-PD Series

Materials

Body: Glass Reinforced Polyamide

Connections

NPT: 1/2″ to 3/4″

Pulse Output

for Water Meters

Learn what Pulse Output is and compare the water meters available with this feature.

Accessories

for Water Meters

See all of the accessories offered for our water meters.