Why Valve Design Matters in Oxygen PSA Generators

The growing use of oxygen PSA (Pressure Swing Adsorption) systems in medical, industrial, and environmental applications has made valve design a critical engineering priority. These systems depend on precision, cleanliness, and reliability.

Unlike nitrogen PSA or other gas applications, oxygen systems present unique challenges. The gas itself is highly reactive. Even small impurities or material incompatibilities can lead to oxidation, system failures, or, in worst cases, combustion hazards.

Choosing the right valve isn’t just about compact design or actuation method. It’s about ensuring safety, purity, and consistent performance—the three pillars of reliability in oxygen PSA systems.

Assured Automation has published several articles on PSA systems, offering engineers valuable insights into valve selection and automation best practices. Explore all PSA-related resources here.

Understanding Oxygen PSA System Operation

A PSA oxygen generator separates oxygen from compressed air by using adsorbent materials that capture nitrogen under pressure and release oxygen during depressurization. The process runs in alternating cycles, typically across twin towers, which rely on precise valve timing.

Valves in these systems:

- Open and close thousands of times per day.

- Must maintain consistent flow and pressure balance.

- Operate under fluctuating conditions of temperature and humidity.

If valves fail to seal properly or if leakage occurs, system efficiency drops. Purity levels decline. More importantly, uncontrolled oxygen flow increases the risk of ignition or mechanical stress.

That’s why selecting the right valve design is central to reliable PSA operation.

Safety First: Material Compatibility and Oxygen Cleanliness

Oxygen-enriched environments demand materials and assembly practices that prevent combustion or degradation. Many metals and lubricants that perform well in standard air or nitrogen systems can become dangerous in oxygen service.

Key considerations include:

- Use of oxygen-compatible metals: 316 stainless steel and brass are common choices.

- Proper seal materials: PTFE or fluorocarbon seals rated for oxygen service prevent degradation.

- Lubrication control: Eliminate hydrocarbon-based lubricants that can ignite in oxygen-rich atmospheres.

- Oxygen cleaning: Valves must be cleaned to remove oils, greases, and particles before service. Standards such as CGA G-4.1 and ASTM G93 define proper cleaning and verification methods for oxygen service.

A best practice is to source valves that are “cleaned for oxygen service” and verified by the manufacturer. It ensures peace of mind when working with high-purity or medical-grade oxygen.

Purity Control: Preventing Contamination and Leakage

Even minor contamination can compromise PSA oxygen purity and damage the adsorbent media inside the towers. That’s why purity control begins with valve design.

Engineers should look for:

- Bubble-tight shutoff: Prevents backflow and cross-contamination between tower cycles.

- Low internal volume: Reduces the amount of trapped gas that can mix between cycles.

- Minimal dead space: Maintains consistent gas composition.

- Clean flow paths: Smooth internal surfaces reduce particle shedding.

Valves such as the Ares Angle Seat and RSG Series are ideal for oxygen PSA generators. Their clean flow paths, bubble-tight shutoff, and compact pneumatic actuation help maintain purity and prevent contamination.

Reliable sealing performance not only preserves oxygen purity but also extends the life of filters and adsorbents downstream.

Performance and Reliability: Valves Built for Repetitive Cycles

PSA systems are relentless. In a 24-hour operation, valves may cycle tens of thousands of times. Components that aren’t designed for this level of use fail quickly, leading to downtime and costly maintenance.

Important design attributes include:

- Cycle-tested seals and stems: Ensure consistent performance over millions of operations.

- Corrosion-resistant construction: Protects against moisture and condensate.

- Actuator durability: Pneumatic actuators with consistent torque output prevent seat wear and sticking.

- Energy efficiency: Low air consumption reduces system demand on compressors.

High-cycle valve designs, such as the VA Series and 26 Series, excel in PSA and air-dryer applications, providing proven reliability through millions of cycles with minimal maintenance.

When you’re working with oxygen systems, consistent performance isn’t optional—it’s essential. The longer a valve maintains its sealing integrity and torque stability, the more efficient and reliable the PSA generator becomes.

Automation and Control Considerations

In modern PSA systems, valve actuation is synchronized with control logic that regulates the timing of adsorption and desorption. Actuator reliability directly impacts oxygen output and energy consumption.

Key automation factors to consider:

- Response time: Faster actuation improves cycle precision and oxygen recovery rate.

- Fail-safe operation: Spring-return actuators are preferred for safety-critical systems because they automatically return valves to their default position in the event of power loss.

- Feedback and monitoring: Position sensors and limit switches enable remote diagnostics and predictive maintenance.

- Air quality: Use filtered, dry air to prevent actuator sticking or sluggish operation.

For larger systems that require automated operation, High-Performance Butterfly Valves offer reliable control with minimal torque and excellent sealing in oxygen-enriched environments.

Selecting actuators that combine tight control, fast response, and minimal maintenance ensures smoother system performance and reduced downtime.

Putting It All Together: Selecting Valves for Oxygen PSA Applications

To summarize, every valve in an oxygen PSA generator contributes to the system’s overall performance. The key is to balance safety, purity, and reliability within the constraints of pressure, temperature, and automation.

Safety

- Choose oxygen-rated materials and seals.

- Verify oxygen-clean assembly and testing.

Purity

- Ensure bubble-tight shutoff.

- Avoid dead space and contaminants.

Performance

- Specify cycle-tested valves and actuators.

- Integrate responsive automation for consistent timing.

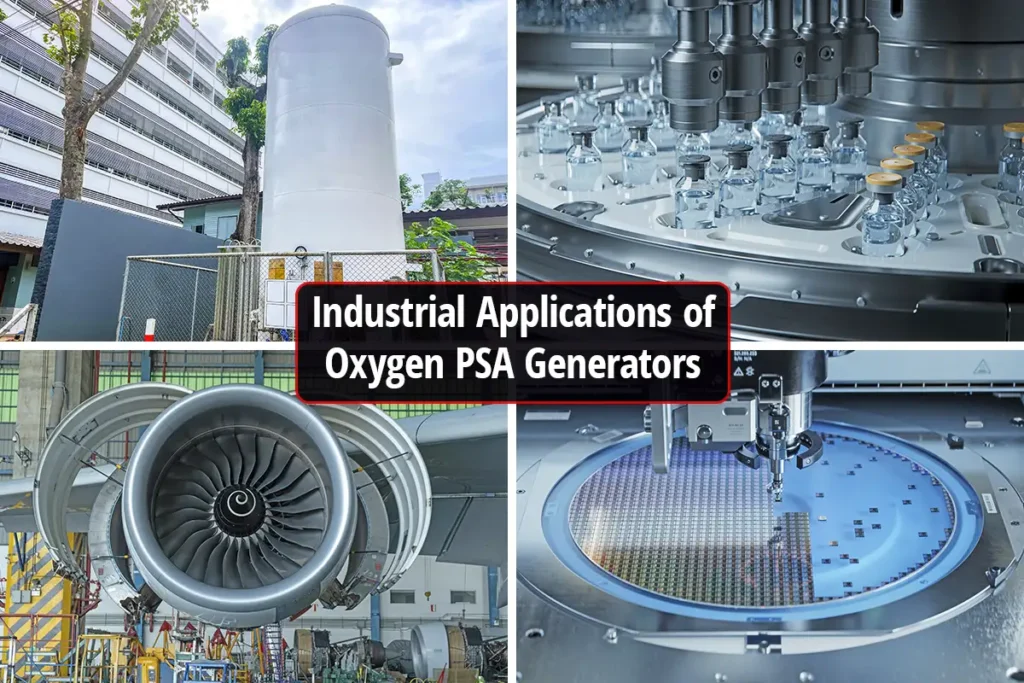

A well-designed valve solution prevents costly downtime, protects sensitive components, and maintains the oxygen purity demanded by today’s industries—from healthcare and food processing to semiconductor fabrication and metal cutting.

Valves used in oxygen PSA generators must do more than open and close. They safeguard system integrity, ensure oxygen purity, and uphold safety standards.

Assured Automation offers a full range of cleaned-for-oxygen-service valves and precision pneumatic actuators designed for continuous-duty applications. Each valve is built to deliver repeatable performance and safety in demanding environments.

Contact Assured Automation’s experts for help selecting the right valves for oxygen PSA generators and other high-purity gas systems. Their engineers can help you specify the ideal solution for your process requirements, ensuring long-term reliability and peace of mind.