VIP-EVO high-pressure coaxial valves are designed and engineered to help OEMs and system designers get more speed, reliability, and performance from their systems. In demanding applications—where fast actuation, tight shut-off, and long service life are critical—these valves offer a compact, efficient solution that stands up to high pressures and high cycle counts—up to 10 times longer life than a ball valve.

Whether you’re building systems for automation, compressed gas control, or fire suppression, choosing the right valve can make the difference between smooth operation and costly downtime.

This blog will walk you through what makes VIP-EVO high-pressure coaxial valves different, where they’re used, and why engineers turn to them for system performance optimization.

Watch our VA Series: Valve + Actuator Training Presentation.

What Makes VIP-EVO High-Pressure Coaxial Valves Different from Traditional Ball Valves

For engineers used to ball valves, coaxial valve technology can seem unfamiliar. But once you look closer, the differences are clear—and worth considering.

Unlike conventional ball valve setups, VIP-EVO features a pneumatically actuated coaxial design with the actuator built into the body. This compact footprint saves space inside equipment panels and skid systems. It also means fewer parts to assemble, service, or align.

For a quick comparison, read our earlier blog, “Coaxial Valves vs. Ball Valves for On/Off Applications.”

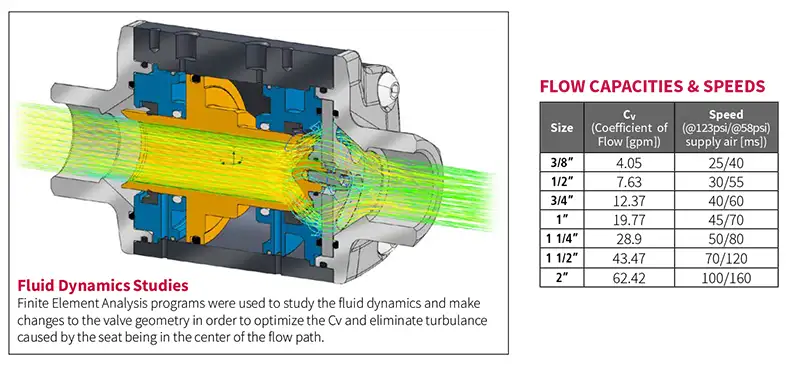

As expected, there are some trade-offs: coaxial valves have lower Cv (flow coefficient) values than ball valves. However, the VIP-EVO design offers clear advantages in applications where fast response, tight shut-off, and long cycle life matter more than max flow.

Key design and engineering benefits:

- Smaller size than equivalent ball valve + actuator setups

- No exposed moving parts for improved safety

- Integrated actuator makes installation faster and cleaner

- 40% less air consumption when compared with conventional actuated ball valves

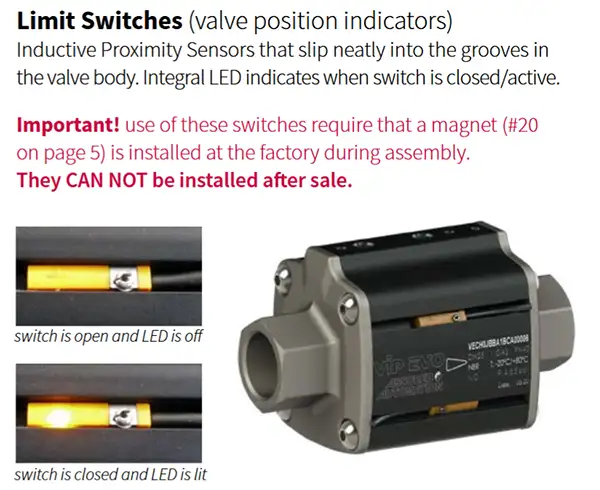

- Optional limit switch indicators mount flush—no bulky protrusions

Applications That Push Valves to Max Performance

VIP-EVO high-pressure coaxial valves are used in a wide range of systems. These are not theoretical applications—they reflect the real-world conditions where coaxial valves outperform traditional options like ball valves.

Pneumatic & Automation Systems

In high-speed pick-and-place robotics, timing is everything. VIP-EVO high-pressure coaxial valves enable fast switching between vacuum (20–28 inHg) and tool air (100–300 PSI), improving throughput without sacrificing accuracy.

In packaging lines, they control actuators and air motors operating at 200–400 PSI, helping to keep products moving and packaging consistent.

Industrial Process Control & Fluid Handling

Compressed air and nitrogen systems need high-cycle, tight-sealing valves to manage constant pressure changes without introducing leaks. The VIP-EVO High-Pressure Coaxial Valve is a solid choice for dual-tower desiccant dryers and plastic injection molding machines, where reliability and fast response are crucial to avoiding moisture contamination or production delays.

In spray coating and atomization processes, valves need to operate rapidly and withstand repetitive actuation at 300–500 PSI. VIP-EVO provides consistent control to high-speed spray nozzles used in painting, chemical treatments, and food processing.

Fire Suppression & Safety Systems

Data centers and industrial facilities rely on fire suppression systems that must respond instantly. VIP-EVO high-pressure coaxial valves are used in CO₂ discharge systems and high-pressure water mist systems (400–580 PSI) where precision and reliability during emergencies are critical. These applications demand fast-acting valves with no margin for error.

Medical, Lab & Testing Equipment

In oxygen and medical gas systems (100–500 PSI), valve performance affects patient safety and system uptime. VIP-EVO’s fast response and long cycle life help minimize risk and downtime. The same applies to pressure and vacuum test benches, where repeatability, tight seals, and support for fast cycling.

Automotive & Heavy Equipment

Hydraulic gear shift systems in off-road and construction vehicles rely on valves that can handle high pressures and high cycle rates (250–500 PSI). VIP series coaxial valves are also used in CNG and LPG fuel switching, where fast actuation under pressure ensures smooth operation and fuel efficiency.

Built for Speed and Long-Term Reliability

In many of the above applications, engineers turn to VIP-EVO high-pressure coaxial valves not for maximum flow—but for fast actuation, compact size, and long-term performance.

The VIP-EVO’s internal coaxial design allows the valve to switch states quickly with minimal air consumption. It’s rated for over 1 million cycles, making it ideal for high-duty equipment like test stands, drying systems, and automated assembly lines.

This extended cycle life helps reduce planned and unplanned maintenance. That means fewer shutdowns, fewer valve replacements, and less time spent troubleshooting.

Simply put, VIP-EVO high-pressure coaxial valves help keep your system running longer, smoother, and with fewer interruptions.

Why Engineers Choose VIP-EVO for Demanding Applications

- Built for speed, high-cycle life, and high-pressure control

- Compact, integrated actuator design saves space and simplifies maintenance

- Ideal for OEMs in automation, testing, fire protection, and fluid handling

- Fewer moving parts, less air consumption, and minimal downtime

- Backed by downloadable CAD models and datasheets for easy integration

Simplified Maintenance and Operational Cost Savings

The VIP-EVO also scores points for ease of service. Since the actuator and valve are integrated, both actuator seals and valve seals can be serviced in a single procedure. That simplifies technician training and cuts down on maintenance steps.

Air consumption is another area where this valve shines. While data varies by application, you can safely estimate substantially lower air usage than older ball valve assemblies. That’s meaningful over time—especially in systems running 24/7 or powered by compressors.

In OEM settings, these design advantages translate to:

- Significant lower cost of ownership

- Smaller enclosure requirements

- Less energy used due to smaller air volume consumed per cycle

- Quicker installation and commissioning

- SIL 3 approved/certified

Best Practices for Specifying VIP-EVO High-Pressure Coaxial Valves

When selecting high-pressure valves, engineers often overlook the long-term costs of valve life and air use. While flow rates matter, other factors—like actuation speed, cycle life, and downtime risks—deserve equal weight.

Here are a few things to keep in mind:

- Be mindful of over-torquing during installation (a common mistake)

- Consider operating pressure ranges (VIP-EVO handles up to 580 PSI)

- Plan for maintenance: the integrated design simplifies seal replacements

- Use our CAD downloads and datasheets to confirm fit and integration

You can access VIP-EVO datasheets and 3D CAD files directly from the VIP-EVO configurator to streamline your design and procurement process.

Ready to Upgrade Your System Performance?

VIP-EVO offers a reliable, compact solution with a proven performance record if you specify valves for a high-pressure, high-cycle application.

- Need to size or configure a valve? Use our online configurator or access CAD models to integrate directly into your design.

- Have questions or complex requirements? Talk to one of our knowledgeable engineers through live chat, phone (1-800-899-0553), or email—we’re ready to help.

- Prefer to order now? Buy directly from our online store.