When handling flammable and combustible liquids, safety isn’t optional—it’s a code requirement. The NFPA 30 Flammable and Combustible Liquids Code establishes the standards for storing, transferring, and protecting these liquids to minimize the risk of fire. One critical aspect of compliance involves valve selection, particularly when it comes to thermal shutoff and emergency shutdown functions. (See Selecting Fire Safety Shut-down Valves).

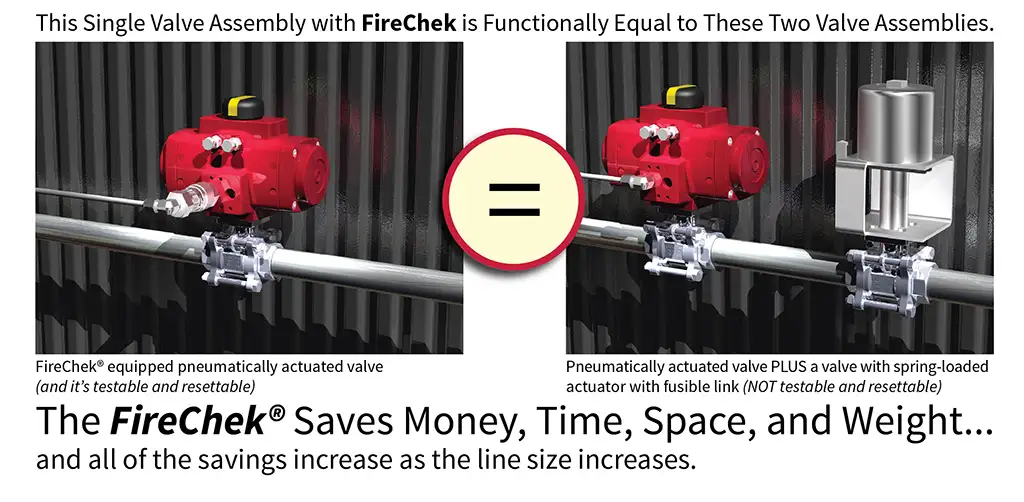

The NFPA Code requires an automated valve and a heat-activated valve for each tank with flammable liquid, which typically means two separate assemblies.

This is where solutions like Assured Automation’s FireChek® and ESD Series come in. FireChek adds thermal shutoff capability to a spring-return pneumatic actuator, effectively transforming it into an emergency shut-down (ESD) valve that satisfies NFPA’s dual requirements in one package.

What NFPA 30 Requires for Flammable Liquid Tanks

At its core, NFPA 30 is designed to minimize the fire risks of storing and handling flammable and combustible liquids.

When it comes to tanks and their supply lines, the code emphasizes two critical safety measures:

- Thermally Actuated Automatic Shutoff Valves

- Each supply line serving a tank with flammable liquids must include a shutoff valve that closes automatically when exposed to high heat (for example, during a fire).

- These valves act independently of power or operator control. They rely on fusible links or thermal triggers that respond directly to temperature.

- The goal is simple: prevent flammable liquids from feeding a fire if the tank or piping is compromised.

- Automated Emergency Shut-down Capability

- NFPA also requires that tanks be protected by automated shutoff capability under emergency conditions.

- In practice, this means having an actuated valve—commonly a pneumatically operated spring-return design—that can isolate the tank quickly when triggered by a control system, alarm, or detection event.

NFPA acknowledges that maintaining two separate valve assemblies can add complexity and cost. That’s why the code permits the use of a combination valve—a single assembly that provides both thermal shutoff and emergency shut-down (ESD) functions.

This flexibility is important because it allows facilities to reduce equipment footprint, streamline installation, and simplify ongoing maintenance—all while staying compliant with NFPA 30.

The Challenge: Two Valves, More Complexity

Traditionally, meeting NFPA 30 meant using two separate safety devices on each tank supply line:

- An actuated valve to serve as the emergency shut-down (ESD) component.

- A thermally actuated valve to provide heat-responsive shutoff.

While effective, this approach introduces several challenges for operators and maintenance teams:

- Higher cost — two assemblies instead of one.

- Increased footprint — extra piping and fittings in already crowded manifolds.

- More maintenance points — each valve requires inspection, testing, and upkeep to remain compliant.

- Greater installation complexity — additional labor, connections, and potential leak paths.

For facilities managing multiple tanks or handling large volumes of flammable liquids, these challenges can quickly multiply. Engineers often ask the same question: Is there a way to achieve NFPA 30 compliance with less equipment and fewer failure points?

The FireChek Solution: Two Requirements in One Actuated Valve

Assured Automation’s FireChek® FC4 Series addresses NFPA 30’s dual requirement by combining both functions into a single package.

With FireChek, you don’t need two separate valves. It transforms a spring-return actuated valve into an Emergency Shut-down (ESD) valve with built-in thermal shutoff. In other words, the ESD series with FireChek meets both requirements in a single, actuated package.

Our customers ask us, “Would our ESD series cover BOTH requirements?”

Yes, that covers both! It’s an actuated valve with a thermal shutoff added by FireChek.

Why It Matters

- Meets both NFPA 30 requirements (automated ESD + thermally actuated shutoff) in one assembly.

- Reduces cost and footprint compared to installing two separate valve assemblies.

- Simplifies compliance with fewer components to inspect, test, and maintain.

- Enhances reliability — fewer leak paths, quicker installation, and proven thermal response.

By using FireChek with Assured Automation’s family of actuated valves, facilities can confidently comply with NFPA 30 while simplifying their system design.

Also refer to our earlier post, Achieving Compliance with Fire Safety Standards Using FireChek® Emergency Shut-Off Valves.

Assured Automation’s Family of Thermal Shutoff Valves

To help facilities comply with NFPA 30, Assured Automation offers a full range of thermal shutoff solutions designed for different applications and environments.

All of these options are designed with one primary goal in mind: automatic, fail-safe valve closure in the event of fire exposure. Whether the need is for a standalone thermal shutoff or a combination assembly that also performs as an Emergency Shut-down (ESD) valve, Assured Automation has a solution that aligns with NFPA 30 requirements.

Among these solutions, the FireChek FC4 Series stands out because it simplifies compliance by combining two functions into a single assembly. Installed on the actuator’s air supply line, FireChek uses a fusible thermal link that melts at a specified temperature. When exposed to heat, the link releases the actuator’s air supply, allowing the spring-return mechanism to close the valve.

See it in action: Quick FireChek demo. At timestamp 2:05, you’ll see how one assembly replaces two.

The result: a single actuated valve that serves both as an ESD and as a thermal shutoff valve. This design minimizes equipment requirements while ensuring compliance with NFPA 30.

FireChek is now a standard addition to process valves in various industries and is frequently specified in system and skid designs. In October of 2024, Assured Automation proudly sold its 10,000th FireChek valve.

Benefits of Assured Automation’s Thermal Shutoff Solutions

By using Assured Automation’s family of thermal shutoff valves, facilities gain both compliance confidence and operational efficiency:

- Meets NFPA 30 requirements

Provides both automated emergency shut-down and heat-activated shutoff, either with separate devices or a single combination assembly. - Flexible options

Choose from FireChek, FM Fire-Safe, or Electro-Thermal solutions depending on system design and safety requirements. - Lower installed cost

Combination designs, such as FireChek, reduce equipment, piping, and labor costs. - Smaller footprint

One assembly instead of two saves space in crowded manifolds or tank farms. - Simplified maintenance

Fewer valves and fittings mean easier inspection, testing, and compliance checks. - Enhanced reliability

Proven designs ensure automatic, fail-safe operation even if power or controls are compromised during a fire.

Whether you require a dedicated thermal shutoff valve or a dual-function solution, Assured Automation offers options that simplify NFPA 30 compliance, making it straightforward, cost-effective, and dependable.

Best Practices for NFPA 30 Compliance

Selecting the correct valve is only one part of meeting NFPA 30. Facilities that handle flammable and combustible liquids should take a holistic approach to compliance and fire protection. Consider these best practices:

- Work closely with fire protection engineers and AHJs

Codes are often interpreted locally. Confirm that your chosen valve assemblies and system design are acceptable to the Authority Having Jurisdiction (AHJ). - Use listed and approved components

Where required, ensure tanks, IBCs, valves, and fittings carry the appropriate listings and labels (e.g., UL 2368 for nonmetallic IBCs). - Integrate with fire suppression systems

Thermal shutoff and ESD valves should work in concert with sprinklers, foam systems, or other fire protection systems outlined in NFPA 30. - Inspect and test regularly

A valve that doesn’t actuate when needed is a liability. Routine testing and maintenance are crucial to maintaining system reliability. - Document your compliance strategy

Keep records of equipment selection, testing, and inspection. Clear documentation makes regulatory reviews and insurance audits far easier. - Plan for redundancy

In critical systems, consider backup valves or multiple layers of protection. This extra margin can be the difference between a controlled event and a major incident.

By following these practices, facilities can exceed basic compliance and establish a stronger fire safety culture that protects both people and assets.

Simplifying NFPA 30 Compliance with Assured Automation

NFPA 30 sets clear expectations for protecting tanks and supply lines that handle flammable and combustible liquids. Compliance requires both automated emergency shut-down and heat-activated thermal shutoff functions — but that doesn’t mean facilities need to overcomplicate their systems with multiple valve assemblies.

Assured Automation’s family of thermal shutoff valves, including the FireChek®, FM Fire-Safe, and Electro-Thermal designs, provide flexible, reliable, and cost-effective solutions for meeting NFPA 30 requirements. Whether you need a standalone thermal shutoff or a combination assembly that delivers both functions in one, Assured Automation offers proven options to help you protect people, property, and operations.

Contact our experts today to learn how Assured Automation’s thermal shutoff solutions can streamline your compliance strategy and improve fire safety in your facility.