FireChek® emergency shut-off valves ensure fire safety compliance. It is critical for industries handling flammable materials, such as oil and gas, chemical processing, and liquefied natural gas (LNG). These sectors must comply with strict regulations set by organizations like the National Fire Protection Association (NFPA) and the Occupational Safety and Health Administration (OSHA). Compliance ensures the safety of personnel, equipment, and the environment.

A key component in maintaining this safety is the implementation of reliable emergency shut-off systems. One such solution is the FireChek® emergency shut-off valve, designed to enhance compliance and mitigate risks associated with industrial fires.

The Role of Emergency Shut-Off Valves in Fire Safety Compliance

Emergency shut-off valves are crucial for stopping the flow of flammable or toxic substances during emergencies, thereby preventing the escalation of hazardous events.

US fire departments responded to an estimated average of 3,396 structure fires involving hot work each year from 2017 to 2021. These fires caused an estimated yearly average of 19 civilian deaths, 120 civilian injuries, and $292 million in direct property damage. (Source: NFPA Research).

Standard fusible plugs have a major limitation—their functionality remains uncertain until an emergency occurs. FireChek® emergency shut-off valves eliminate this uncertainty because they are testable and resettable by design. As an FM-approved solution, FireChek® delivers proven effectiveness in high-risk environments.

Imagine the safety and lower risks to firefighters because “they don’t come into a fire with extra air feeding the fire and the noise accompanied with 100psi hissing air.”

How FireChek® Emergency Shut-Off Valves Work

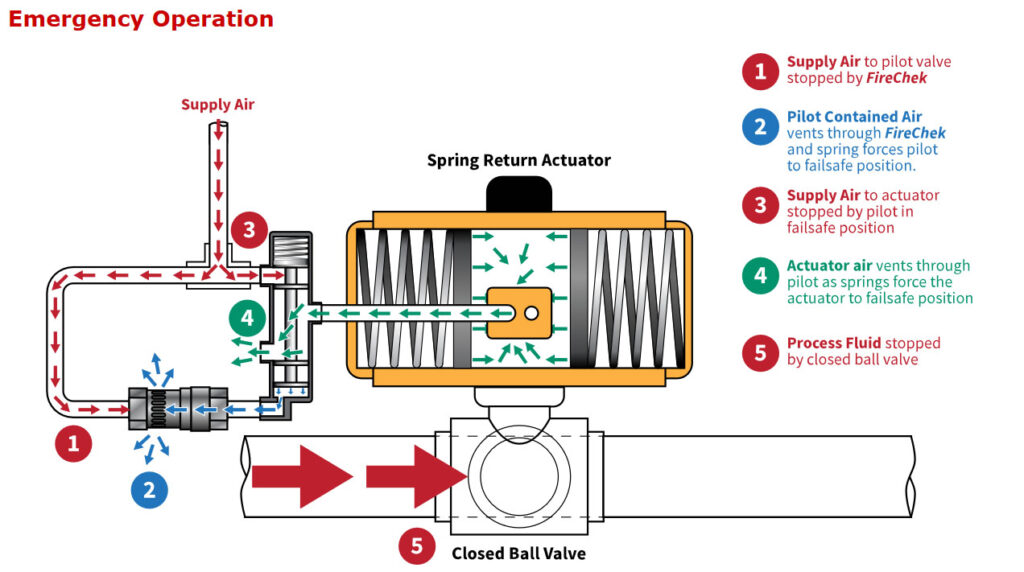

FireChek® valves are thermally actuated devices that respond to ambient temperature changes. They utilize a shape memory alloy, such as Nitinol, which transforms at predetermined temperatures (135°F, 150°F, or 165°F). Upon reaching the set temperature, the alloy activates the valve to block the instrument supply air and vent the actuator. This action prevents additional air from feeding a fire, a critical factor in controlling industrial fires.

By design, FireChek® offers a significant advantage over other methods that require full replacement after activation. Testing and resetting are possible using a heat gun. Its functionality is easily restored by a simple twist by hand after it has cooled.

By responding to rising temperatures, FireChek® automatically blocks instrument air supply and vents the actuator, preventing continued fuel flow to a fire.

View our quick overview video of the FireChek®

Real-World Applications of FireChek®

FireChek® valves are used in various industries to enhance fire safety measures:

- Fuel Storage Terminals: FireChek® valves ensure rapid response during fire emergencies, preventing the spread of fire to stored flammable materials.

- Rail Car Emergency Shut-Down (ESD) Systems: Integrated into rail car systems transporting hazardous materials, FireChek® valves provide an automatic safety mechanism in case of fire.

- Storage Tank Valves: Used in storage tanks containing flammable liquids, FireChek® valves offer an additional layer of protection by automatically shutting off flow during high-temperature scenarios.

- Chemical Processing Facilities: Prevents the accidental release of toxic substances by shutting off process valves when fire hazards are detected, reducing environmental and safety risks.

These applications highlight the versatility and reliability of FireChek® valves in real-world settings, addressing common challenges engineers face in maintaining fire safety compliance.

Installation, Maintenance, and Performance Considerations

When specifying emergency shut-off valves, engineers should consider the following factors:

- Resettable Thermal Shutoff: The ability to test and reset the valve without component replacement ensures ongoing reliability and compliance with safety protocols.

- Ease of Retrofit: FireChek® valves can be added to existing process valves without affecting their normal operation, offering flexibility in upgrading safety systems.

- Compact Design: Their compact size allows for installation in various settings, accommodating actuators of all sizes with appropriate accessories.

Cost Savings & ROI:

Beyond fire safety compliance, FireChek® valves offer cost advantages for engineers and plant managers looking to optimize their safety systems without excessive capital investment:

- Retrofit Instead of Replace: FireChek® can be added to an existing automated valve assembly, eliminating the need to replace the entire unit. This extends the lifespan of current systems and reduces capital expenditures.

- Minimized Downtime & Manual Intervention: Since FireChek® is resettable and maintenance-free, it significantly reduces operational costs associated with system shutdowns, manual resets, and emergency service calls. This ensures uninterrupted operation while maintaining compliance with fire safety regulations.

To better understand how FireChek® compares to other emergency shutdown and isolation valves, read the article “The Pros and Cons of 3 Types of Emergency Shutdown and Emergency Isolation Valves.”

Industry Trends and Common Misconceptions

While significant recent regulatory changes have not affected shut-off valve selection, the emphasis on safety and compliance is still as important. A common misconception is that all fire safety shut-off valves are “set and forget” devices. However, not all valves offer the testability and reset capability of FireChek®, making it a standout choice for proactive safety management.

Key Takeaways:

- Enhanced Compliance: FireChek® valves assist industries in meeting stringent fire safety standards set by organizations like NFPA and OSHA.

- Resettable and Testable: Unlike traditional fusible plugs, FireChek® valves can be tested and reset by a simple twist by hand after it cools, ensuring ongoing reliability.

- Versatile Applications: Suitable for various industries, including fuel storage, rail transport, and chemical processing.

- Maintenance-Free Design: Requires no maintenance unless exposed to an actual fire, reducing operational costs.

- Compact and Retrofit-Friendly: Easily integrated into existing systems without affecting normal operations.

Proven Reliability with 10,000+ FireChek® Emergency Shut-Off Valves Sold

Over 10,000 FireChek® emergency shut-off valves have been installed across industries, providing trusted fire safety compliance for fuel storage terminals, rail car ESD systems, and storage tanks. This milestone reflects FireChek’s reliability and effectiveness in protecting industrial operations from fire hazards.

Ready to Enhance Fire Safety with FireChek®?

If you’re looking for FM-approved shut-off valves that improve fire safety compliance and provide reliable emergency isolation, FireChek® is the proven choice.

- Ready to buy? Configure and order FireChek® directly from our website for quick and hassle-free purchasing.

- Have questions or need help with a custom project? Our knowledgeable valve experts are here to help. Start a live chat, email us, or call 800-899-0553 today to discuss your specific application needs. We Make Valve Automation Easy!

NOTE: The FireChek is FM Approved. Valve Assemblies that use it are not.