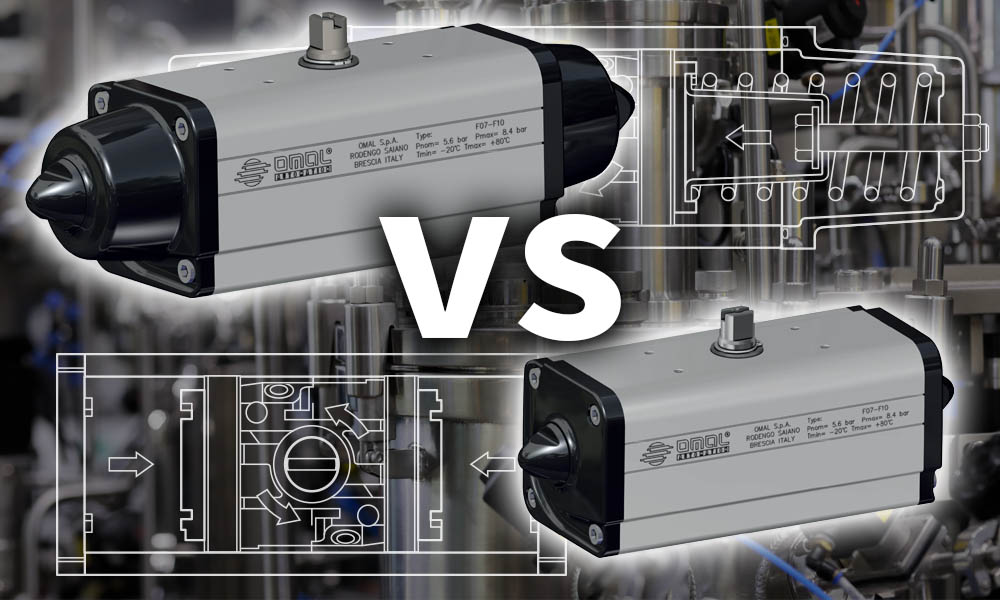

Double-acting vs. spring return actuators, which one is right? You’ve asked yourself that question when selecting actuators for valves. You’re probably familiar with the two most common types: spring return and double-acting. But choosing between them isn’t always straightforward—especially when safety, energy use, or fail-safe behavior is on the line.

Many engineers and buyers default to spring return actuators because of their built-in fail-safe action. Others assume double-acting actuators are the simpler, more cost-effective option. The truth is both types have strengths, trade-offs, and ideal use cases. Choosing the wrong one can lead to system inefficiencies, unexpected behavior during power loss, or even safety risks.

In this blog, I’ll break down how each actuator type works, the key factors to consider, and when one option clearly outperforms the other—so you can make the right decision for your application.

Double-Acting vs. Spring Return Actuators Explained

At a glance, the main difference between spring return and double-acting actuators is what happens during a loss of air or power.

- Spring Return Actuators (also known as single-acting) use compressed air or electricity to move the valve in one direction. Built-in springs return the valve to its “fail-safe” position when power or pressure is lost. This is ideal when the system must default to open or closed for safety or containment.

- Double-Acting Actuators (also know as direct-acting), on the other hand, require air or electric power to move the valve in both directions. They do not have springs to drive the valve to a default position. Instead, they stay in place on loss of air—making them effectively fail-in-place. But, if electricity is lost, the actuator will travel to the position they take when the solenoid is de-energized—assuming there is still sufficient air pressure in the system.

It’s important to note that “fail-in-place” isn’t always a disadvantage. In some systems, keeping a valve frozen in its last known position is actually the preferred behavior. For example, failing to open or close automatically in certain processes or dosing applications could lead to overfill, spillage, or material waste.

Actuation speed may also vary. Spring return actuators tend to slow down as the spring compresses while double-acting actuators typically offer more consistent stroke speed—though the difference is often minimal.

In terms of popularity, spring return actuators are more common at Assured Automation—largely due to buyer preference for fail-safe behavior, even when it isn’t strictly required. But fail-safe isn’t always optional. As one of our engineers puts it:

“A good rule of thumb is—If an uncontrolled valve position upon power failure could harm people, the environment, or damage equipment or waste valuable material, a fail-safe actuator is required.”

For a more in-depth understanding, read the research study, “Efficacy of Using the Double-Acting Hydraulic Cylinder.”

Key Factors to Consider When Choosing Between Spring Return and Double-Acting Actuators

Choosing the right actuator isn’t just about how it moves a valve—it’s about understanding the trade-offs that affect cost, performance, and risk. Below are the five most important factors to consider when comparing spring return and double-acting actuators.

1. Size and Footprint

Spring return actuators are usually bulkier and longer than their double-acting counterparts. That’s because the spring mechanism requires additional space, and in many cases, a larger actuator body is needed to deliver enough force to overcome both the valve torque and the spring resistance.

By contrast, double-acting actuators are typically more compact. A smaller double-acting actuator may be better if space is limited or weight is a concern—such as on mobile equipment or densely packed skid systems.

2. Cost: Upfront and Lifecycle

Double-acting actuators are usually more affordable if you compare apples to apples. They’re smaller and don’t include springs, which reduces material costs. Maintenance costs also tend to be lower over the actuator’s life since there are fewer moving parts under mechanical tension.

Spring return actuators may cost more upfront, and over time, springs can degrade—especially in high-cycle applications. While they don’t fail often, spring fatigue can eventually slow response time or affect the fail-safe stroke.

3. Fail-Safe Requirements

This is often the deciding factor. If your process must default to a known position during a power or air failure, a spring return actuator is the clear choice. It offers a true mechanical fail-safe that doesn’t rely on external energy.

Double-acting actuators are fail-in-place under air loss. That might be fine—or even preferred—in systems where you don’t want valves to open or close automatically. If power loss is the only concern, most systems will still allow the actuator to make one final stroke using residual air pressure. But it’s not guaranteed and won’t work if air is also lost.

If a fail-safe action is critical but air supply is unreliable, electric actuators may be worth considering as an alternative. There are 3 different types of fail-safe electric actuators.

- Capacitive Return: The actuator cycles counter-clockwise when power is supplied. It includes a capacitor that starts charging while this happens. It continues charging while the valve is held in that position. Once power is removed or interrupted, the energy stored in the capacitor is used to cycle the actuator back in the clockwise direction.

- Battery Backup: Similar to the Capacitive return actuators above, these actuators simply use a battery instead of a capacitor. When power is lost, the valve will travel to the preferred position.

- True “Spring Return”: These actuators use an actual spring. When power is lost, the drive train disengages and the spring drives the actuator to the desired position.

4. Air Consumption

Spring return actuators use air for only one direction of movement. Double-acting actuators need air to drive the valve in both directions, meaning nearly double the air usage under normal operation.

This difference can become a meaningful cost or design constraint in high-cycle systems or facilities with limited air supply. For most standard operations, though, air consumption isn’t a major decision driver—unless energy efficiency or compressor capacity is a concern.

5. Service Life and Spring Fatigue

Spring return actuators perform reliably for years, but springs compress every cycle. Over time, this can lead to slower strokes or unbalanced motion between the air-driven and spring-driven sides.

Signs of spring fatigue include:

- The return stroke becomes slower

- The air-driven stroke speeds up disproportionately

- End-of-travel sensors trigger with increasing delay

Preventative maintenance can extend spring life. For critical systems, limit switches combined with stroke timers in the control system can help detect performance drift before it causes a problem.

Application Scenarios—When One Type of Actuator is Better Than the Other

While technical specs matter, real-world applications often make the decision clearer. Here are a few scenarios where one actuator type fits perfectly:

Use Spring Return When:

- Fail-safe is critical – as with batching systems, chemical feed lines, or tank overfill prevention. If a valve must automatically close to stop flow on loss of air or power, spring return is the right choice.

- City water pressure or gravity feed drives the system – where uncontrolled flow can lead to flooding or spillage. Even low-pressure sources can create risk if valves don’t default to a safe position.

- Environmental or personnel safety concerns – a spring return actuator helps prevent harm, contamination, or damage when control is lost, addressing environmental or personnel safety concerns.

Use Double-Acting When:

- Size and weight are limiting factors – for mobile equipment, compact skids, or applications where actuator clearance is tight.

- Prefer fail-in-place – In some process control applications, holding a valve steady during a power failure prevents material waste or line shock.

- Cost or air supply constraints matter – DA actuators are smaller, more cost-effective, and more efficient when the system doesn’t need constant fail-safe capability.

To summarize, think of spring return as the safety-first default—and double-acting as the streamlined choice when safety, air usage, or valve default position aren’t major concerns.

How Assured Automation Helps You Decide

Even with a clear understanding of actuator types, many engineers still ask, “Which one should I use for this valve, in this application?”

That’s where Assured Automation adds real value. We offer multiple ways to simplify actuator selection:

- Online configurators with pre-sized assemblies based on 60 or 80 psi air supply pressure

- Side-by-side comparisons of size, price, and weight from three trusted brands: Omal (P Series), Elomatic (F Series), and Allied (C Series)

- Detailed technical datasheets and assembly-specific documentation (For example, See F Series datasheet)

- CAD models on demand to evaluate fit and layout in your own system (Watch video)

- One-on-one support via phone, email, or chat with experts who know these products inside and out

Whether your concern is actuator performance, compliance, or simply making sure everything fits and works as expected, we’ll help you get it right the first time.

We Make Valve Automation Easy—because that’s exactly what you should expect from a supplier partner.

Choosing between spring return and double-acting actuators isn’t just about personal preference but operational safety, cost, and system efficiency and reliability. Here’s what to remember:

- Spring return actuators provide true fail-safe behavior—ideal when system safety is on the line

- Double-acting actuators are compact, cost-effective, and efficient—best when fail-in-place is acceptable or preferred

- Key selection factors include size, air usage, cycle life, and maintenance

- There’s no one-size-fits-all answer—the right choice depends on your application

Need help selecting the right actuator?

Call us at 1-800-899-0553, start a chat, or explore our configurators online. Whether you need peace of mind or precision performance, Assured Automation is here to help.

We Make Valve Automation Easy.