Every minute of data center downtime can cost thousands, and fire is among the most disruptive risks operators face. Traditional suppression systems, such as sprinklers or gas-based agents, only respond after a fire has started, often causing additional damage in the process.

That’s why a growing number of data centers are turning to a smarter approach: oxygen reduction systems (ORS). Also known as hypoxic air systems, these technologies continuously lower oxygen concentration in server rooms to levels that prevent combustion but remain safe for personnel. It’s a proactive way to mitigate fire risk—without the delays, mess, or downtime of conventional suppression methods.

In this blog, we’ll explore how oxygen reduction systems work, their role in modern data center safety strategies, and how reliable flow control with VA valves from Assured Automation supports long-term system performance.

Our VA Series product video provides a helpful overview of how these valves function and what makes them stand out in demanding environments.

Why Fire Prevention Matters in Data Centers

Fires in data centers may be rare, but when they happen, the consequences are severe—ranging from costly downtime to complete data loss. According to a Uptime Institute study, 43% of data center outages cost more than $100,000, and fire-related incidents are among the most disruptive.

The problem is that conventional fire suppression systems are reactive by design. Sprinklers can damage electronics, and gas-based systems, while cleaner, require equipment shutdowns, recharging, and careful sealing of the space. Both approaches aim to extinguish a fire only after it has ignited.

That’s why interest is growing in continuous, passive fire prevention solutions—especially in hyperscale and high-density environments, where increased airflow and electrical load heighten the risk of fire.

A shift from reactive to preventive thinking is driving demand for technologies like oxygen reduction systems that can mitigate fire risk 24/7 without interfering with daily operations.

What is an Oxygen Reduction (Hypoxic Air) System?

At its core, an oxygen reduction system creates an environment where fire cannot start in the first place. It works by continuously displacing a portion of the oxygen in the air with nitrogen, harmless to humans but hostile to flames.

The result is a stable atmosphere with reduced oxygen concentration, typically around 14–15%, which is too low to support combustion but still safe for personnel under most conditions.

To understand the concept, consider the three elements required for fire: fuel, heat, and oxygen. This is often referred to as the fire triangle. Remove any one of these, and fire can’t occur.

ORS targets the oxygen leg of that triangle—not by flooding the room in response to heat or smoke, but by keeping oxygen levels consistently below the ignition threshold.

Nitrogen generators or high-purity compressed nitrogen sources feed the system, often controlled by automated valves and sensors that maintain the target concentration. The goal is stability, avoiding fluctuations that could allow ignition conditions to return. That makes precision and reliability essential, especially in mission-critical environments like data centers.

For readers interested in other ways valves are used in data center systems, see our related blog: How Sanitary Valves Are Gaining Interest in Data Center Cooling Systems.

Benefits and Challenges of Hypoxic Air Solutions

Oxygen reduction systems offer a compelling set of benefits for data center fire prevention, especially in environments where uptime, cleanliness, and equipment safety are non-negotiable. But like any system, they also come with design and operational challenges that must be considered upfront.

Key Benefits

- Proactive Fire Prevention

Unlike reactive suppression systems, ORS solutions work continuously to prevent ignition. By maintaining oxygen levels at around 14–15%, they interrupt the conditions necessary for combustion, thereby protecting assets without the need for emergency intervention. - No Water or Residue

Hypoxic systems avoid the collateral damage caused by water-based sprinklers or chemical clean agents. There’s no risk to sensitive electronics, and no cleanup is required after a fire event—because ideally, there is no fire. - Safe for Occupants

The reduced oxygen levels are comparable to those found at high altitudes. For most healthy personnel, this is perfectly tolerable, allowing for normal access to server rooms without the need for special breathing equipment. - Minimal Downtime

Since the system operates continuously in the background, there’s no need to shut down operations or evacuate areas during activation—another major difference from inert gas or water mist systems. - Compliance and Insurance Advantages

Many ORS technologies meet global fire safety standards, including FM Global’s FM‑5580 approval for oxygen reduction fire prevention systems. This can support code compliance and may improve insurability.

Design and Operational Challenges

- Precision Control is Critical

Maintaining a stable reduced oxygen level requires reliable sensors, feedback systems, and responsive flow control. Even small fluctuations could allow ignition or trigger alarms. - Room Integrity is Essential

Leaks in room seals or air handling systems can compromise oxygen levels and reduce the system’s effectiveness. Proper enclosure design and airtightness are crucial. - Initial Cost and Infrastructure

ORS systems often require nitrogen generators or bulk storage, along with monitoring and control systems, to ensure optimal performance. While operational costs are low, the upfront installation costs can be higher than those of traditional suppression systems. - Occupational Safety Considerations

While generally safe, hypoxic environments may not be suitable for all personnel. Training and signage are needed to ensure staff understand the environment and respond appropriately.

The Critical Role of Valves in Oxygen Reduction Systems

In any oxygen reduction system (ORS), precision isn’t just important—it’s essential. These systems rely on a continuous and carefully measured flow of nitrogen to maintain safe and stable hypoxic conditions. That means the performance of the valves used to control that flow can make or break the system’s reliability.

Why Valves Matter in ORS Design

The core function of an ORS is to lower and maintain oxygen concentration by injecting nitrogen into the protected space. Valves control the amount of nitrogen entering, the rate at which it enters, and their response to specific signals, typically from oxygen sensors and a central control panel. A poorly timed or imprecise valve can lead to unstable oxygen levels, false alarms, or worse—failure to prevent ignition.

Because ORS systems must run continuously and often in sensitive environments like data centers, their valves need to deliver:

- Consistent Flow Control: Sudden spikes or drops in nitrogen flow can cause fluctuations in oxygen levels. A high-quality valve ensures steady delivery under varying conditions.

- Fast, Reliable Actuation: ORS systems may need to adjust flow quickly in response to sensor data. Valves must open or close reliably under repeated cycling.

Challenges with Generic Valve Selection

Not all valves are suited for ORS. Some common issues with off-the-shelf or improperly specified valves include:

- Outgassing or contamination that interferes with high-purity nitrogen delivery.

- Inconsistent response times or failure under frequent cycling.

- Inadequate pressure or flow handling for the system’s requirements.

- Lack of documentation or testing for oxygen service or clean media.

This is where specialized valves—like Assured Automation’s VA Series—offer a significant advantage, which we’ll explore in the next section.

How Assured Automation’s VA Valves Support Oxygen Reduction System Reliability

In oxygen reduction systems, even the best-designed nitrogen generation and control setup is only as reliable as its weakest component. That’s why valve performance is critical—especially when uptime, precision, and safety are non-negotiable. Assured Automation’s VA Series valves are well-suited for ORS applications thanks to their durability, clean operation, and oxygen-rated design.

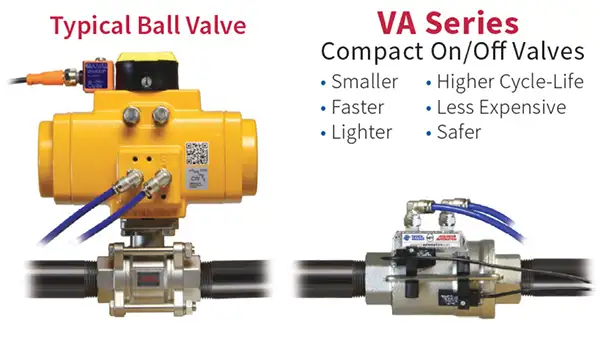

Engineered for High-Cycle, Clean Service

The VA Series combines a pneumatic actuator and a fast on-off control valve into one body, eliminating the need for packing glands, actuators, and mounting kits. This compact, all-in-one design reduces potential leak points and simplifies installation, an advantage in space-constrained mechanical rooms often found in data centers.

The Operating life has been tested to well over 1,000,000 cycles.

Because ORS applications often require oxygen-clean or inert gas-compatible materials, VA valves are available with degreased internals and components rated for oxygen service. This eliminates the risk of combustion from contaminants—a critical consideration in systems where even trace hydrocarbons can pose a hazard.

Size Comparison

Side-by-side comparison of a 1” NPT 36 series pneumatically actuated ball valve vs. a VA series coaxial valve with integral actuator.

Fast, Reliable Actuation with Fail-Safe Options

VA valves are available in normally open or normally closed configurations and can be equipped with integral solenoid valves in 12VDC, 24VDC, 24VAC, 120VAC or 220VAC models. This allows precise remote operation, tied to oxygen sensors and system controllers, ensuring responsive flow adjustments as needed.

These features make the VA Series especially well-suited for use in ORS setups that require:

- Precise control of nitrogen injection

- Clean operation for high-purity gas service

- Compact design for integration into tight mechanical rooms

- Reliability under continuous or cycling conditions

Support and Resources You Can Trust

In addition to robust engineering, Assured Automation provides application support and resources to help you specify the right valve for your system.

If you’re designing or upgrading an oxygen reduction system and need confidence in your flow control components, make sure your valve selection supports the precision and performance your application demands. The VA Series is worth serious consideration. Assured Automation’s VA Series valves are engineered for clean, high-cycle service, making them a dependable choice for ORS designers and facility managers who can’t afford system failures or inconsistencies.

Ready to Strengthen Fire Prevention in Your Data Center?

Oxygen reduction systems provide a smarter, more proactive approach to minimizing fire risk in today’s high-density data centers. But the effectiveness of these systems depends heavily on the reliability of every component—especially the valves controlling nitrogen flow.

Talk to one of our VA Series experts. Contact us today.