| Order Online or Call Toll-Free 1-800-899-0553 | Log-in/Create Account |

|

|

We Make Valve Automation Easy

|

| Order Online or Call Toll-Free 1-800-899-0553 | Log-in/Create Account |

|

|

We Make Valve Automation Easy

|

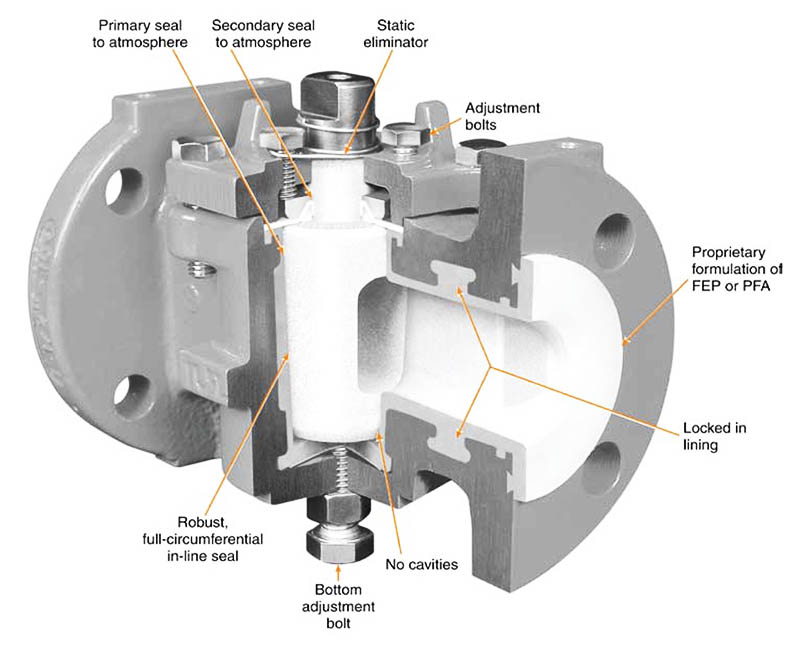

A continuous primary seal results from the interaction of the tapered plug and the tapered body bore. Cast-in ribs behind the body lining concentrate compression of the lining between the ribs and the plug. This assures a full circumferential in-line seal. There is also a full circumferential seal around the plug, both above and below the flow passage. There are no cavities where flow media can accumulate or contaminate.

The three adjustment bolts in the cover and the bottom adjustment bolt work together to assure a maximum sealing capability and an extended service life.

In addition to the primary seals, there is a secondary seal system consisting of interacting components. The secondary stem seals, located above the plug, protect against external leakage up to 400°F.

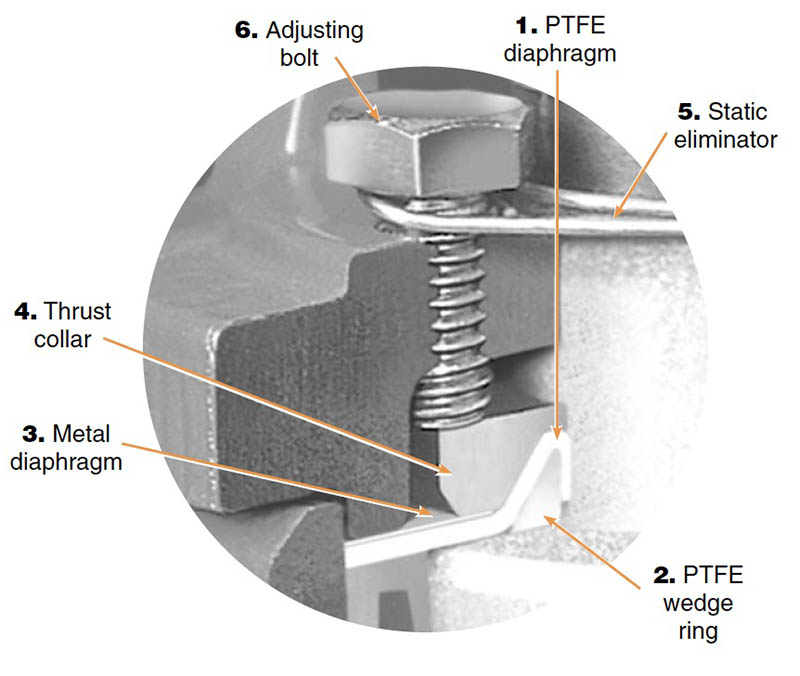

1. The PTFE diaphragm is shaped into an inverted V at its inner circumference. It seals at the cover joint and against the plug shank.

2. To help assure positive sealing and easy adjustment, the PTFE wedge ring fits into the V-formed inner circumference of the PTFE diaphragm. Sealing force is transmitted from the thrust collar (4) through the wedge ring.

3. A metal diaphragm is above the PTFE diaphragm and wedge ring. This metal diaphragm provides metal-to-metal contact at the cover joint. This prevents cold-flow of the PTFE diaphragm. This configuration provides two independent compression seals between the body and the cover. One seal is plastic; the second is metal.

4. On top of the metal diaphragm is a floating thrust collar which acts to assure uniform pressure on all sealing surfaces.

5. Above the cover, on the plug shank of wrench operated valves, is a static eliminator which provides a positive electrical ground between the body and the plug.

6. Three adjusting bolts in the cover impart downward force through the thrust collar (4), to the wedge ring (2), then to the inner leg of the inverted “V” of the PTFE diaphragm (1). This, together with the opposing force of the plug, provides a pressure assisted seal which is not adversely affected by plug movement. The adjusting bolts also facilitate quick and easy adjustment of in-line sealing.