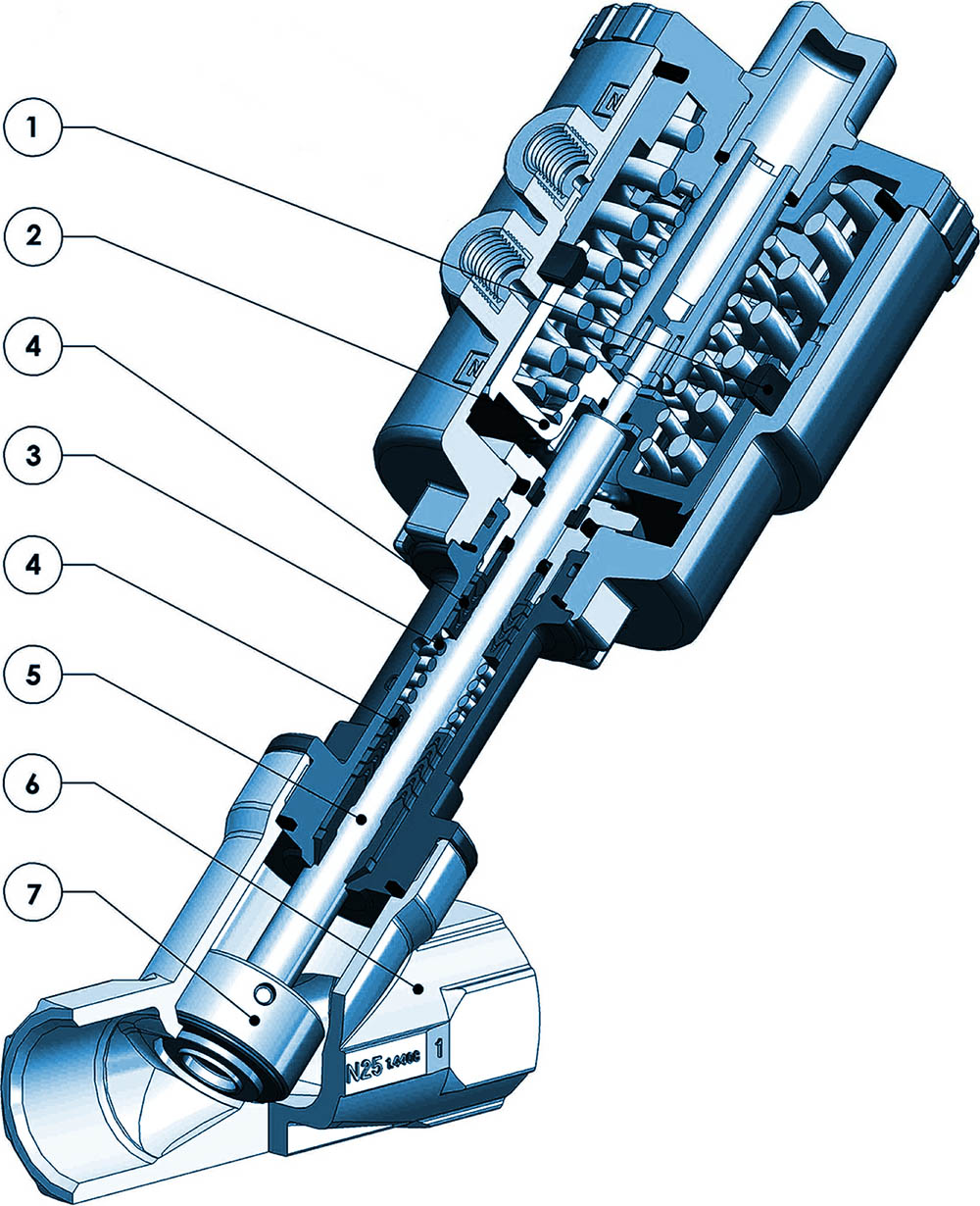

| 1) |

Lip seal placed in the cylinder rather than on the piston |

Longer stroke of the actuator and shutter will be achieved, providing higher flow rate (less flow loss).

Less wear of the seal |

| 2) |

Metallic piston with CHEMICAL NICKEL coating (10-15 micron) |

Reduces the wear of the piston due to the achievement of agreater surface hardness (700-750 HV) |

| 3) |

Seals pre-loaded by spring |

Allow to maintain energized the "chevron" seals (V) compensating the dimensional changes even in case of huge temperature fluctuations |

| 4) |

CHEVRON seals (V shape) with 5 seals in the lower part of the spring and 3 seals in the upper part |

It ensures a perfect tightness even after a high number of cycles |

| 5) |

Rolled shaft |

Less wear of the seals due to the low roughness (0,1 micron Radius) which facilitate the sliding of the shaft |

| 6) |

Investment cast body |

Better fluidodynamic and reduction of the turbulence |

| 7) |

Self-aligning seat |

It fits perfectly to the valve body ensuring the maximum

tightness |