- Class VI shut-off, Bubble tight

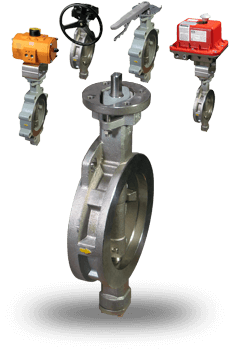

- Advanced Seat Design:

provides a bi-directional interference and pressure assisted seal. This provides maximum seal at high, medium and low pressures

- Extended Neck:

Allows for up to two inches of pipe insulation

- Positive Seal Packing Design:

PTFE is a cup and cone system and Graphite is die formed rings

- Graphite Impregnated or Reinforced 316 SS Bearings:

ensure long service life

- High Strength 17-4 ph SS Stem:

provides maximum strength for high-torque applications

- Quick-Release Disc Design:

reduces amount of torque needed to un-seat disc.

- Disc Taper Pins:

Pins are offset from the center of the stem which places them in compression rather than in sheer. This gives them a yield point greater than the stem itself.

- Integrally Cast Disc Position Stop:

Machined position stop on the body locates the disc in the seat to achieve maximum seat and seal life.

Materials

- Body: Carbon Steel or Stainless Steel

- Disc: 316 Stainless Steel

- Seats: RPTFE

End Connections

- Wafer: 2"

to 12"

- Lugged: 2"

to 12"

Temperature Range:

- -4°F to 450°F

see P/T curve

Pressure Range:

- ANSI 150: 285 PSIG

- ANSI 300: 740 PSIG

see P/T curve

Dead End Service: (Lugged Connections Only)