| Order Online or Call Toll-Free 1-800-899-0553 | Log-in/Create Account |

Adds Thermal Shutdown to ANY spring

return pneumatic actuator!

anAssured Automation

anAssured AutomationExclusive!

•Vents actuator to failsafe

•Closes air supply line

•Easy to test and reset

•No contact with process media

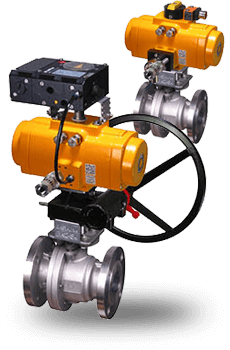

Pneumatic Actuators

Pneumatic Actuators

Ball&Butterfly Shut-Off Valves

Automated valve assemblies with

Emergency Shutdown Function included

with Fusible Links

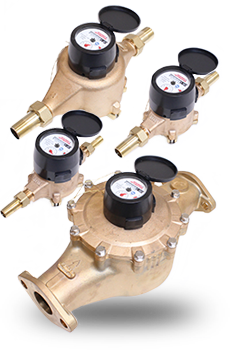

Automatic Batch Controller

-How Many Gallons Do You Want?

•Low-Cost

•Easy to Use

•Selection of Meters

•Selection of Valves

Seals:Viton,EPDM,or Buna

End Conn:Ni plated Brass(wetted)

Piston:Chem.Ni plated Brass(wetted)

Seat:PTFE 15%Glass FiberSeals:Viton,EPDM,or Buna

G(BSPP):3/8" to 2"

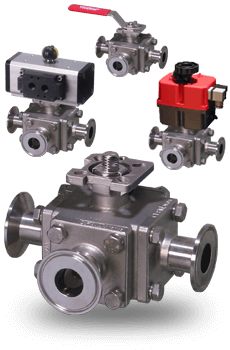

Seals:PTFE

Tri-Clamp:1/2" to 2"

Seals:EPDM or Viton

Seats:PTFE

Glue Socket:1/2" to 4"

Seals:PTFE

Seats:RPTFE

Socket Weld:1/2" to 3"

Tri-clamp:1/2" to 4"Ext.Tube Butt Weld:1/2" to 4"

Seals:PTFE

Seats:RPTFE

Socket Weld:1/4" to 3"

Tri-clamp:1/2" to 4"

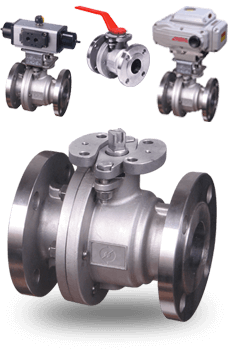

Seals:TFM or Graphite

Seats:TFM or 50/50

300#:1/2" to 8"

Seals:TFM or Graphite

Seats:TFM or 50/50

300#:1/2" to 8"

Seals:TFM or Graphite

Seats:TFM or 50/50

Socket Weld:1/2" to 4"

Seals:TFM or Graphite

Seats:TFM or 50/50

Socket Weld:1/2" to 4"

Seals:TFM or Graphite

Seats:TFM or 50/50

Socket Weld:1/2" to 4"

Trim:API Trim 8(others available)

300#,600#,900#,1500#:Call

Seats:PTFE,TFM,or 50/50

Seats:PTFE,TFM,or 50/50

150#/300#:1/2" to 8"

Tri-Clamp:1/2" to 4"

Seats:PTFE

Seals:PTFE/Viton or RPTFE

Seats:TFM

Seals:TFM

300#:1 1/2" to 6"

Seats:PTFE

Seats:EPDM or Viton

Glue Socket:1/2" to 2"

Seats:EPDM,SIlicon,or Viton

Butt Weld:1/2" to 6"

Seats:Polypropylene

Lugged:2 1/2" to 12"

Seats:RPTFE

Lugged:2" to 12"

Seats:Graphite

Lugged:3" to 48"

ANSI class 150,300,600

Seats:Graphite

Lugged:3" to 48"

ANSI class 150,300,600

Seats:BUNA or EPDM

Lugged:2" to 24"

Seats:Viton

Lugged:2" to 24"

Plug:PFA Lined Ductile Iron

Seals:PTFE,RPTFE,PFA,or Special

300#:1/2" to 12"

Trim:SS,TFE,or PEEK

300#:1/2" to 4"

NPT:1/2" to 2"

SW:1/2" to 2"

Trim:Bronze,SS,or PEEK

Butt Weld:1/2" to 2"

Trim:Bronze or SS

300# Flange:2 1/2" to 8"

Trim:API Trim 8(others available)

300#,600#,900#,1500#:Call

Trim:API Trim 8(others available)

300#,600#,900#,1500#:Call

Seats:PTFE

Seals:PTFE

NPT(male x female):1/4" to 1"

Solder:1/2" to 4"

Socket Weld:1/4" to 3"

Tri-Clamp:1/2" to 3"

Seats:PTFE

Seals:PTFE

NPT(male c female):1/4" to 1"

Solder:1/2" to 4"

Socket Weld:1/4" to 3"

Tri-Clamp:1/2" to 3"

Body:Carbon or Stainless Steel

Seals:Delrin®

SW: 1/4"

150#:1/4"

300#: 1/4"

Lugged:1/4"

Wafer: 1/4"

Seals:Graphoil

Seats:Xtreme RPTFE

150#/300#:1/2"to 4"

Lug/Wafer:3"&4"

Seals:TFM or Graphite

Seats:TFM or 50/50

300#:1/2" to 8"

NPT:1/2" to 4"

Socket Weld:1/2" to 4"

Seat:API Trim 8 or 12

Cover Seal:Graphite

300#:2" to 16"

Seals:TFM or Graphite

Seats:TFM or 50/50

300#:1/2"to 8"

Seals:Graphoil

Seats:Xtreme RPTFE

150#/300#:1/2"to 4"

Lug/Wafer:3"&4"

Seals:TFM or Graphite

Seats:TFM or 50/50

Socket Weld:1/2" to 4"

Seals:TFM or Graphite

Seats:TFM or 50/50

Lugged:2" to 12"

Seals:TFM or Graphite

Seats:TFM or 50/50

300#:1/2" to 8"

NPT:1/2" to 4"

Socket Weld:1/2" to 4"

End Caps:Powder coated die-cast aluminum

Double Acting:up to 59,000 in/lbs.

Double Acting:up to 21,430 in/lbs.

Double Acting:up to 25,600 in/lbs.

Double Acting:up to 25,600 in/lbs.

Water:100%removal

Water:100%removal

BSPP:1/4" to 2"

T-clamp:1/2" to 2"

T-clamp:3/4" to 2 1/2"

Flange:1" to 2"

Glue Socket(female):1" to 4"

Flange:3" to 4"

Insertion:1 1/2" to 8"

Insertion:1 1/2" to 8"

Straight forward and easy to understand training materials covering the most important concepts in valve automation.

Read posts about valve applications, case studies, problem/solutions, industry news, and more. Customer reviews of products and testimonials are also included.

View our entire library of videos. Product Overviews, How-to Videos, Wiring Instructions, and more. Subscribe to our YouTube channel to me notified of new additions.

See Assured Automation in the leading industry publications. Whenever we make news, we put a link to it here.W